How Does a Control Board Influence Ice Machine Automation

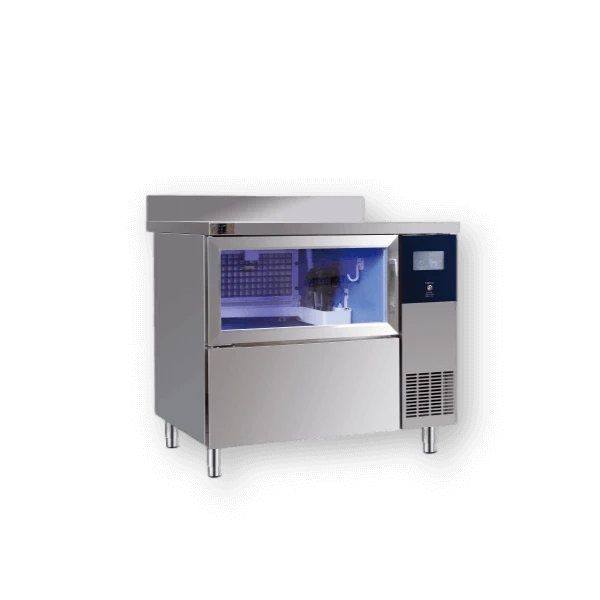

In today’s fast-paced world, automation has found its way into almost every industry, including refrigeration and ice production. As technology advances, businesses are increasingly relying on automated systems to streamline operations, reduce costs, and improve efficiency. One critical component in the automation of ice machines is the control board, which acts as the brain of the system. This article will delve into how a control board influences ice machine automation, with a specific focus on the expertise and innovations brought by JELUMB Refrigeration Equipment (Shanghai) Co., Ltd (JELUMB).

JELUMB, a leading name in the refrigeration and ice machine industry, has consistently pushed the boundaries of technology to deliver state-of-the-art solutions. By integrating advanced control boards into their ice machines, JELUMB has not only enhanced the functionality of their systems but also set new standards for automation in the industry. Let’s explore how control boards work, their significance in ice machine automation, and the broader implications for the industry.

What is a Control Board?

A control board, often referred to as the "brain" of an automated system, is an electronic circuit board that manages and regulates the functions of a machine. In the context of ice machines, the control board is responsible for overseeing the entire ice-making process, from water intake to ice production and storage. It ensures that every component of the machine operates in harmony to deliver optimal performance.

Modern control boards are equipped with microprocessors, sensors, and software algorithms that enable real-time monitoring and adjustments. They can detect anomalies, execute programmed instructions, and even communicate with external systems for remote management. JELUMB has been at the forefront of designing and manufacturing cutting-edge control boards that cater to the specific needs of ice machine automation.

How Control Boards Influence Ice Machine Automation

1. Precision and Consistency

One of the primary roles of a control board is to ensure precision and consistency in ice production. By monitoring parameters such as water temperature, ambient temperature, and compressor performance, the control board can make real-time adjustments to maintain optimal conditions. This results in uniform ice quality and minimizes wastage. JELUMB’s advanced control boards are engineered to deliver unparalleled precision, ensuring that their ice machines produce consistent results even under varying environmental conditions.

2. Energy Efficiency

Energy efficiency is a critical factor in the design and operation of ice machines. Control boards play a pivotal role in optimizing energy consumption by regulating the operation of compressors, fans, and other components. JELUMB’s control boards are equipped with energy-saving algorithms that reduce power usage without compromising performance. This not only lowers operational costs but also aligns with global sustainability goals.

3. Enhanced Diagnostics and Troubleshooting

Modern control boards are designed to facilitate diagnostics and troubleshooting. They can detect and log errors, provide detailed information about system performance, and even suggest corrective actions. JELUMB’s control boards are integrated with user-friendly interfaces that make it easy for operators to identify and resolve issues. This reduces downtime and ensures uninterrupted operation.

4. Remote Monitoring and Control

In an era where connectivity is key, JELUMB has embraced the Internet of Things (IoT) to enhance the functionality of their control boards. By enabling remote monitoring and control, JELUMB’s ice machines can be managed from anywhere in the world. Operators can access real-time data, adjust settings, and receive alerts through their smartphones or computers. This level of automation not only improves convenience but also enhances operational efficiency.

5. Integration with Smart Systems

JELUMB’s control boards are designed to integrate seamlessly with smart building systems and other automated solutions. This allows businesses to create a cohesive ecosystem where ice machines, refrigeration units, and other equipment work together to optimize overall performance. For example, an integrated system can adjust ice production based on demand, reducing energy consumption during off-peak hours.

JELUMB’s Innovations in Control Board Technology

JELUMB has consistently demonstrated its commitment to innovation by investing in research and development. Their control boards are a testament to their expertise and dedication to excellence. Here are some of the key features that set JELUMB’s control boards apart:

Advanced Microprocessors: JELUMB’s control boards are powered by high-performance microprocessors that enable fast and accurate data processing.

Customizable Software: The software algorithms used in JELUMB’s control boards can be tailored to meet the specific requirements of different applications.

Robust Construction: Designed to withstand harsh operating conditions, JELUMB’s control boards are built with durability in mind.

IoT Integration: JELUMB’s control boards are equipped with IoT capabilities, allowing for seamless connectivity and remote management.

User-Friendly Interfaces: JELUMB’s control boards feature intuitive interfaces that make it easy for operators to monitor and control the system.

Implications for the Industry

The advancements in control board technology have far-reaching implications for the ice machine industry and beyond. By enabling higher levels of automation, control boards are transforming the way businesses operate. Here are some of the broader impacts:

Increased Productivity: Automated ice machines can produce ice more efficiently, meeting the demands of high-volume applications such as restaurants, hotels, and industrial facilities.

Reduced Environmental Impact: Energy-efficient control boards contribute to lower carbon emissions, supporting global efforts to combat climate change.

Enhanced Customer Experience: Consistent ice quality and reliable performance enhance customer satisfaction, giving businesses a competitive edge.

Cost Savings: Automation reduces labor costs and minimizes operational expenses, improving profitability.

Conclusion

The control board is undeniably a cornerstone of ice machine automation. By enabling precision, energy efficiency, diagnostics, remote monitoring, and integration with smart systems, control boards have revolutionized the way ice machines operate. JELUMB Refrigeration Equipment (Shanghai) Co., Ltd has been a trailblazer in this field, delivering innovative solutions that set new benchmarks for the industry.

As businesses continue to embrace automation, the role of control boards will only become more significant. With companies like JELUMB leading the charge, the future of ice machine automation looks promising, offering endless possibilities for innovation and growth.

Whether you’re a business owner looking to upgrade your ice production capabilities or an industry professional seeking insights into the latest technological trends, understanding the role of control boards in ice machine automation is essential. And with JELUMB at the forefront, you can be assured of cutting-edge solutions that deliver exceptional performance and value.

EN▼

EN▼ CN

CN FR

FR IT

IT KR

KR

Leave a comment